* УТОЧНЯЙТЕ ВОЗМОЖНОСТЬ, ЦЕНУ И СРОК ПОСТАВКИ, В СВЯЗИ С ОГРАНИЧЕНИЕМ ЭКСПОРТА ТОВАРОВ ИЗ СТРАН ЕС И ВЕЛИКОБРИТАНИИ

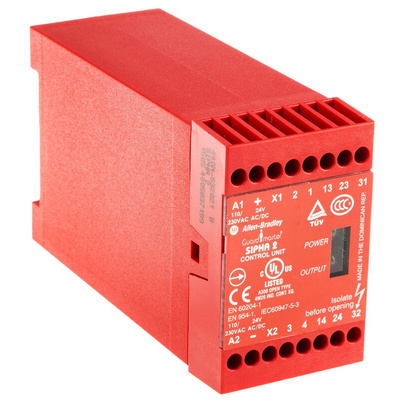

Allen Bradley Guardmaster 440N-S32021 Sipha Control Unit 2

Ensure safe access to machinery and keep personnel protected with the Sipha Control Unit 2 by Allen Bradley Guardmaster. This controller is designed to be used with the Sipha Non-Contact Safety Switches and provides monitoring and control of the sensors.

The 440N-S32021control unit has automatic reset, 24V AC/DC, 115V or 230V AC supply voltage and 2 Normally Open Safety Contacts / 1 Normally Closed Auxiliary Contact. The housing is 45mm and the case is comprised of polycarbonate. This unit can be mounted on a 35mm DIN rail for effortless installation. It has an operating temperature range of -10°C to +55°C (+14° to +131°F). For high-risk applications the controller can be used with a single sensor, providing a high-integrity system. Multiple sensors as well as mechanical switches can be connected to one Sipha controller for other applications. It has facilities for connecting a manual reset button and monitoring external devices such as contactors.

The Sipha Safety Switches feature magnetically sensitive elements which must be activated in a specific sequence to operate correctly, ensuring greater reliability and security for complex applications. They cannot be defeated by a simple magnet. These dependable switches are perfectly suited for use with sliding, hinge, and lift-off safety guards. When the safety barrier is released the power is isolated, preventing dangerous machinery from running while personnel can access it and reducing risk of injury.

Features and Benefits:

• Interfaces for Sipha noncontact safety sensors

• Acts as a safety relay

• 2NO safety contact and 1NC auxiliary contact

• Magnetic coded sensing for superior security

Certifications:

IP67 rated

EN954-1

ISO13849-1

IEC/EN60204-1

NFPA79

EN1088

ISO14119

IEC60947-5-1

IEC/EN60947-5-3

ANSI B11.19

AS4024.1

CE certified

UL listed

TUV certified

Rockwell Automation is a global leader in industrial automation and digital transformation, and brings smart manufacturing to life. With a long legacy of creating Allen-Bradley® integrated control and information solutions, we help make you as productive as possible. Our portfolio of sensing, safety and motor control products can support your move towards smart machine applications. Allen-Bradley® IO-Link sensors are data-enabled and communicate with all field buses, providing diagnostic and health information about the device before a machine stops, and enabling quick production changeovers through fast parameter downloads from PLCs into the device. This reduces machine downtime and increases manufacturing OEE. For safety components, products with built-in diagnostics simplify the set-up of the smart device, and reduce maintenance, leading to a more efficient, machine data-driven approach.

What are magnetically coded non-contact safety switches?

A magnetically coded non-contact switch is a device used for monitoring the position of machine safety barriers. They are typically used in industrial environments. It uses a magnetically-actuated reed contact and a specially-coded actuator. When the barrier is opened the contacts will either open or close due to the magnetic force interrupting the circuit. As there is no contact between the sensor and actuator they take less wear, are resistant to shocks and vibrations, and are highly tamper-proof, which gives them a long service life. They are often used for sliding, hinge, and removable gates.

Техническая спецификация Ferrocode Switch to a Sipha 2 Control Unit Wiring Example

Ferrocode Switch to a Sipha 2 Control Unit Wiring Example Datasheet

Datasheet Machine Guarding and Safety Range Overview

Machine Guarding and Safety Range Overview 440N-S32021 Installation Instructions

440N-S32021 Installation Instructions Safety Switches Technical Data

Safety Switches Technical Data Allen Bradley Safety Switches Brochure

Allen Bradley Safety Switches Brochure| Самовывоз со склада поставщика в Екатеринбурге | Забираете сами или вызываете курьера |

| ТК Деловые Линии | от 500 руб |

| Курьером EMS Почта России | от 500 руб |

| Другой транспортной компанией | По согласованию |